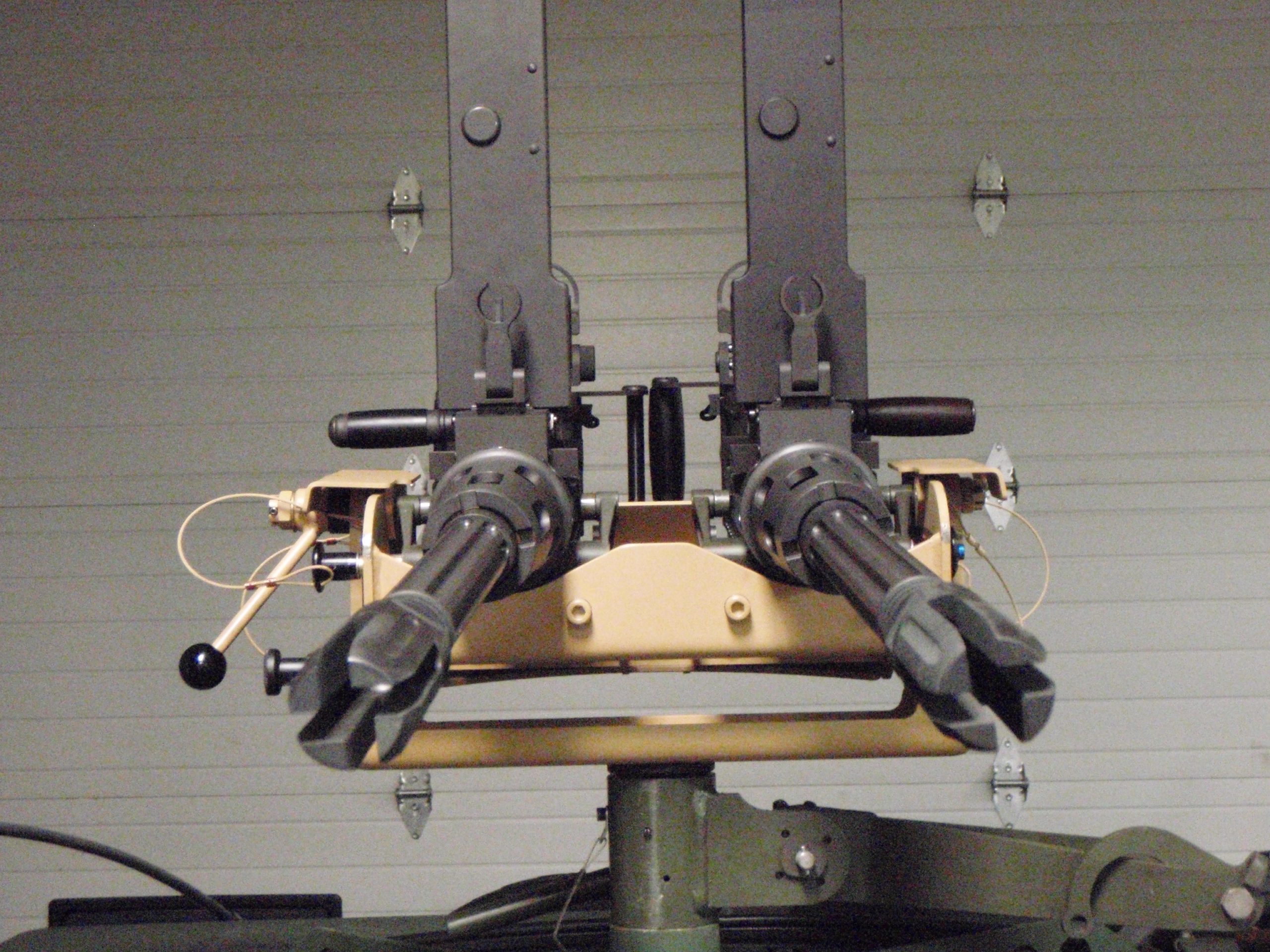

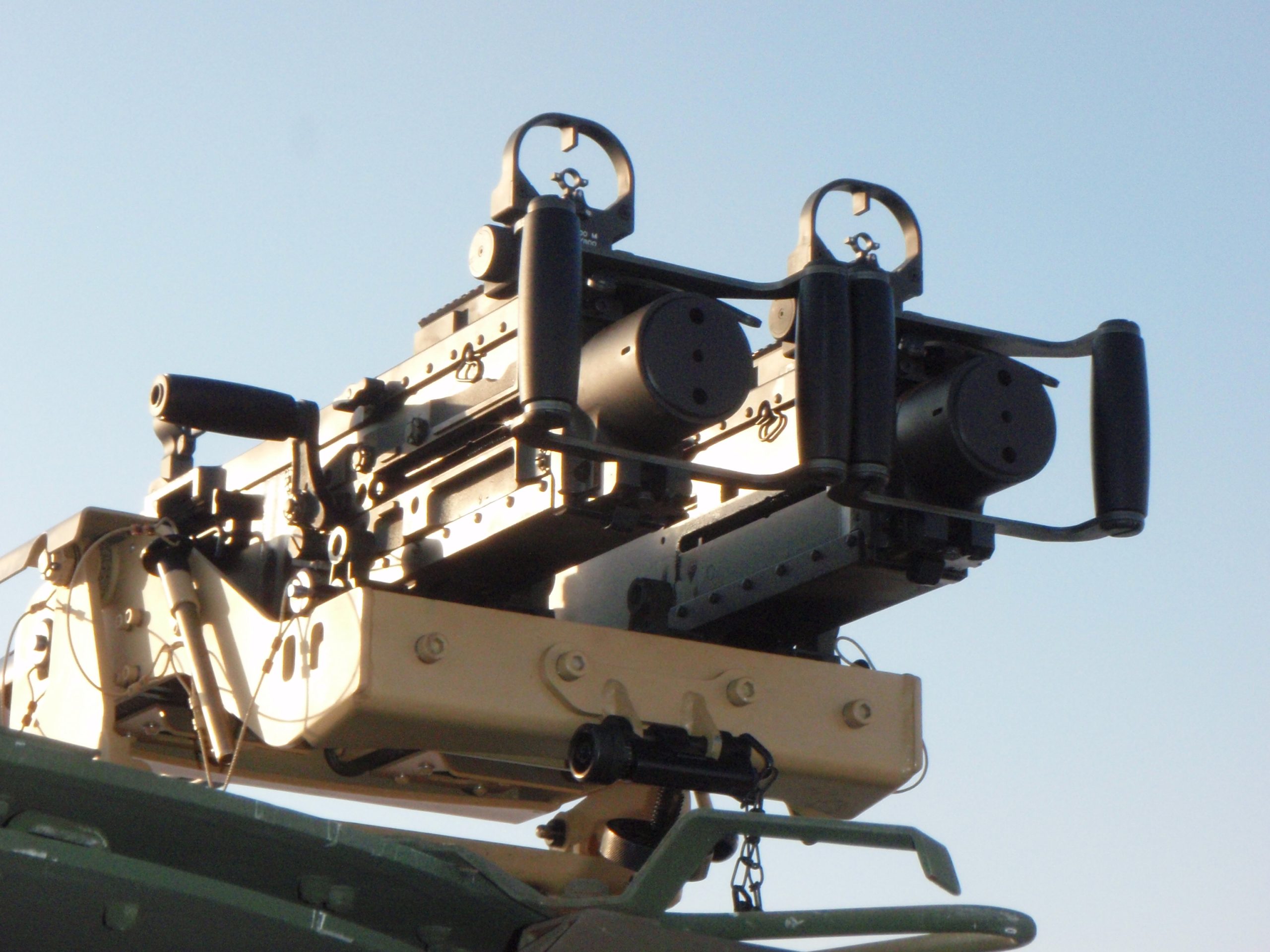

THOR M3DF Heavy Belt-fed Machinegun .50 BMG

Features Overview

- M3 based design

- High rate of fire

- Lighter weight

- Increased accuracy

- Increased reliability

- Simplified maintenance

- Mechanical or electronic fire control

- Fluted barrel

- Improved flash suppressor

- Optional adjustable-rate buffer, sighting systems, open bolt lock

- Made in the USA

Features

- M3 Based Design

- Minimal logistics change required, uses more than 85% NSN components

- High Rate of Fire

- 1,100 rounds per minute (1025 +- 75 rounds per minute)

- Light Weight

- M3D 74.5 lbs

- Linear Bushing System

- Precision axial barrel control allows increased accuracy and reliability due to receiver and internal components operating under less stress

- Simplified Maintenance

- Barrel assembly can be removed through front or rear of receiver

- Mechanical or Electronic Fire Control

- Can use either spade grip back plate, or solenoid fire control

- Improved Flash Suppressor

- Completely eliminates visible flash

- Thicker tangs to improve durability

- Fluted Barrel

- Larger surface area for better barrel cooling

- Improved rigidity over light weight aircraft barrel

- Feeds from either side

- Standard feed chute and cartridge stop configurations for either LH or RH feed

Additional Options

- Open Bolt System/Bolt Lock

- Can operate in either open or closed bolt, or manual bolt lock to reduce dangerous ‘cook off’ situations

- Adjustable Rate Buffer

- Fully sealed, maintenance free, hydraulic design

- Manual knob or electronic rate selection

- Approx 200 round per minute difference

- Advance Combat Sight 50 System from Crane Tactical

- Adapts several additional targeting devices

- PEQ2A IR laser, PAQ4 IR laser, EOTech, or other Weaver rail mounted sights/lasers

- Adapts several additional targeting devices

Service Intervals

Replace the following parts as a minimum every 2,500 rounds:

- Ejector Spring

- Sear

- Sear Slide

- Sear Spring

- Inspection of Feed Pawl and Feed Pawl Springs

Replace the following parts as a minimum every 5,000 rounds:

- Extractor Body

- Sear

- Sear Spring

- Sear Slide

- Sear Slide Stop Pin

- Firing Pin

- Firing Pin Extension

- Feed Pawl Springs

- Inspection of Feed Pawl

Depot maintenance recommended every 50,000 rounds. Receiver life should reach 100k+ rounds like a regular M2/M3.

Support Equipment

- Tripod & Stand Assembly

- W&E Platt

- Ballistic Shield

- Spare Barrel

- Hard Case with wheels

- Firearms Training & Instructions

Field support cleaning kit (Standard 50 Caliber) composed of:

Hot Barrel Mitten

Headspace and Timing Gage (M2HB)

Headspace and Timing Gage (M2HB-QCB)

5 Piece Cleaning Rod w/ T-Handle

Ratcheting Chamber Brush

Bore Brush

Small Bottle LSA

Patch Jag

Replacement parts kits:

Description

For More Information

THOR Global Defense Group, INC.

1206 Knesek Lane

Van Buren, Arkansas, 72956 USA

Phone: +1-479-474-3434

Fax: +1-479-262-6925

Email: info@thorgdg.com

DUNS: #008351722

CAGE: 5RGY1